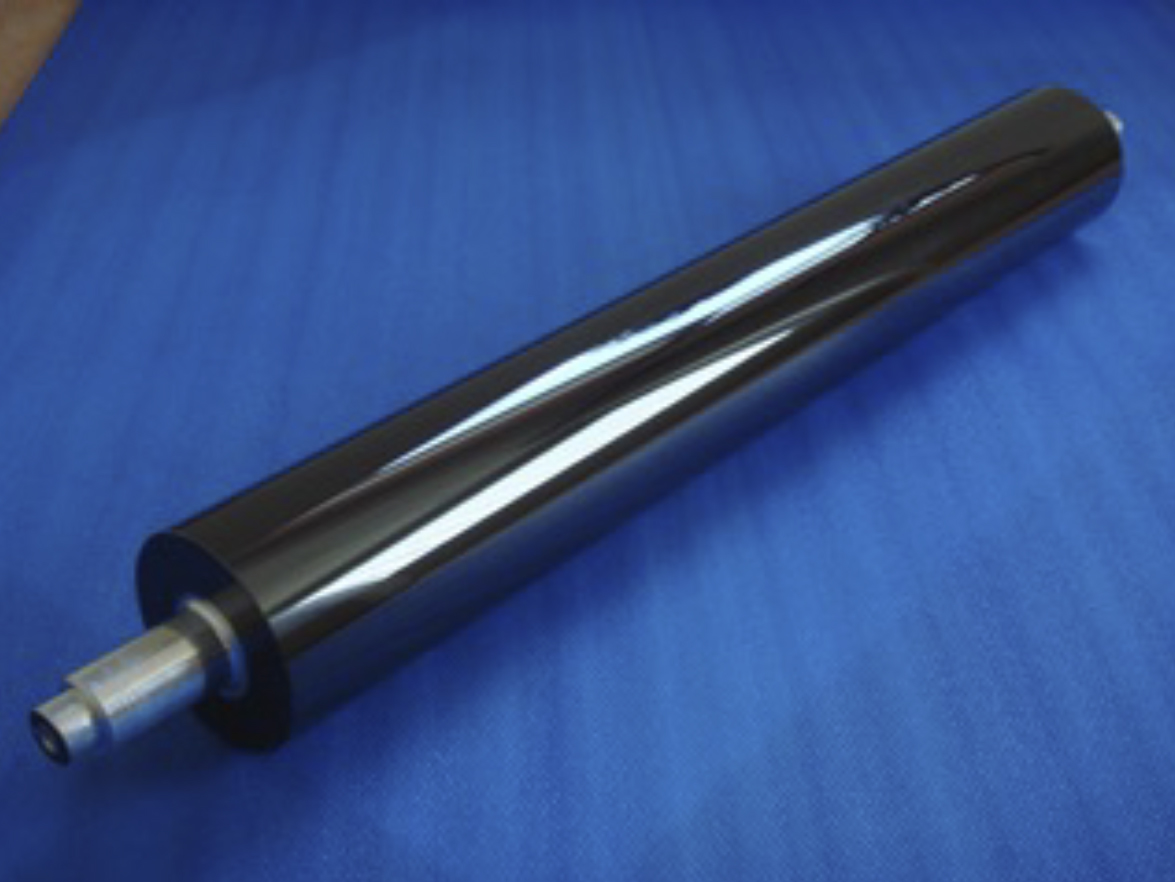

Rolls are becoming more important in the process where improvements in productivity and quality are required amid rapid technology innovation.

Roll Improvements and Proposals

• Provide solutions for troubles attributing to rolls

• Propose lightening rolls

• Deal with troubles due to DLC coatings

• Deal with damages on the film caused by satin rolls (Develop a satin mirror surface roll)

• Improve the roll performance by hybrid coating

• Improve peripheral rolls and provide solutions

• We can handle long rolls (up to 6 m in total length)

Improve Bonding Performance

Provides improved removability and fixability. Prevents wrinkles. Special treatment can be applied onto your rubber roll surface.

Reduce Static Electricity

Prevents static electricity, smears, and wrinkles. Provides improved smoothness, durability, and hydrophilicity. Enables treatment on metal, SUS, Al, HCr, and rubber due to DLC treatment in the range of room temperature.

Eliminate marks from rollers

Provides improved removability and fixability. Prevents wrinkles. Special process can be applied onto your satin guide roll surface.

Eliminate wrinkles

The Nip Roll offers wrinkle prevention and stable feeding due to low tension. Surface treatments can be applied according to the application.

Remove dust and contamination

Equipped with special synthetic rubber, this roll offers excellent adhesion, stability, heat resistance, and durability. The flexible material and soft adhesion provide a uniform and effective dust removal.

Remove moisture

High-performance sponge roll achieving outstanding water absorption in draining the film surface and draining at the manufacturing process of electronic parts such as glass substrates and PCBs and at the drying process of food.

Make roll lighter

Using CFRP (Carbon Fiber Reinforced Plastics) for the shaft, even long rolls can be coated without being affected by their own weight.

Improve peel ability of roll

This is a new surface treatment method for non-adhesive applications that does not require knurling or thermal spraying on metal surfaces.

Improve corrosion & acid resistance

Coating the roll surface with DLC (Diamond-Like Carbon) offers several benefits, know all of them here.

Precision Double-Sided Coating Equipment for Film

This device is designed for thin base materials (copper foil 10µm, film total 12.5µm) and can coat both sides of a thick substrate (2mm) with very uniform film thicknesses.

By coating and drying both sides simultaneously, the process time is reduced, increasing productivity.

Compatible Board Size:

- Minimum: 360 x 360mm

- Maximum: 600 x 600mm

Production Capacity:

- Up to 6 pieces per minute

The unique 4-head chucking system allows for smooth coating, preventing wrinkles.

Application Examples:

- Coating of photoresist and solder resist for PCB and FPC

- Coating of AG/AR ink on optical film

- Coating of engineering plastics with hard coat agents

- Coating of functional resin on metal foil

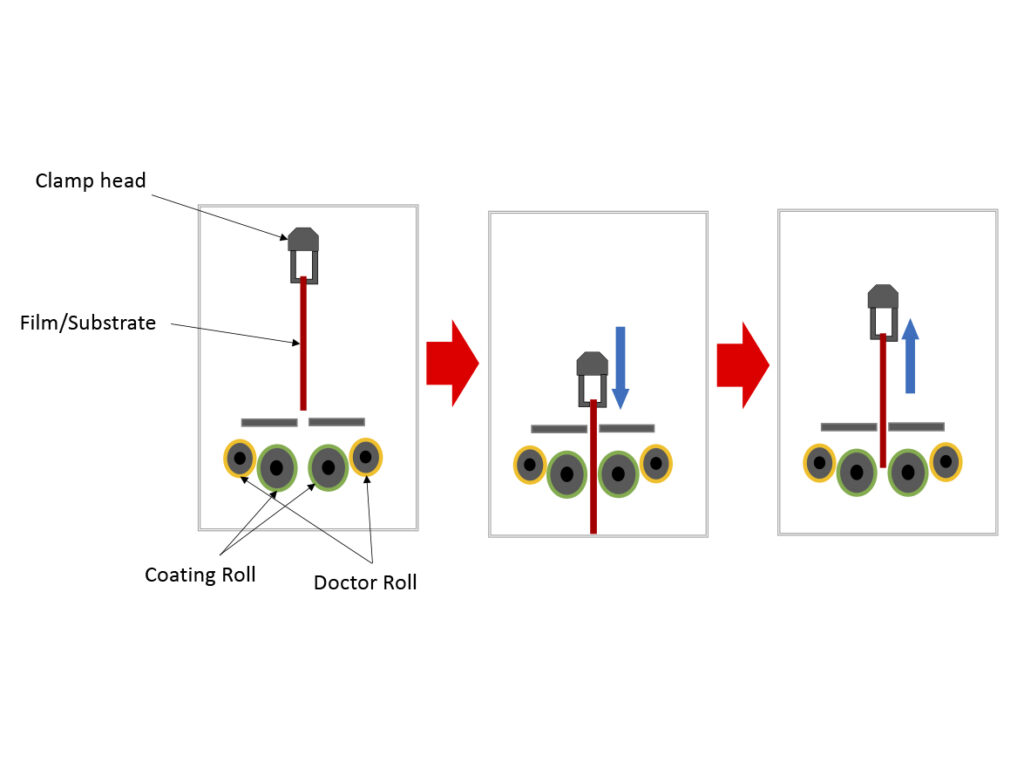

Tabletop Type Single-Side Coating Device

For evaluation and trial purposes, coatings ranging from 100nm to 1mm can be achieved by simply changing the rolls. The simple structure makes handling easy. Stable rotation is obtained through control with a brushless motor, adopting a direct drive method. The coating direction can be switched between forward and reverse. The Doctor roll, coating roll, and backup roll can each be controlled individually. It can be used with a 100V power supply. Adjustments between rolls can be made in 1/100th minute increments.

Purpose:

Solar glass panels

Glass for building materials

Wallpaper for building materials

Mobile resin

Stainless Steel plates

Motor Core

Iron Plate

LED panel

Back sheet for solar cell panels

Panel for building materials

Plastic resin

Printed Circuit boards

Functional Materials

Leather sheets