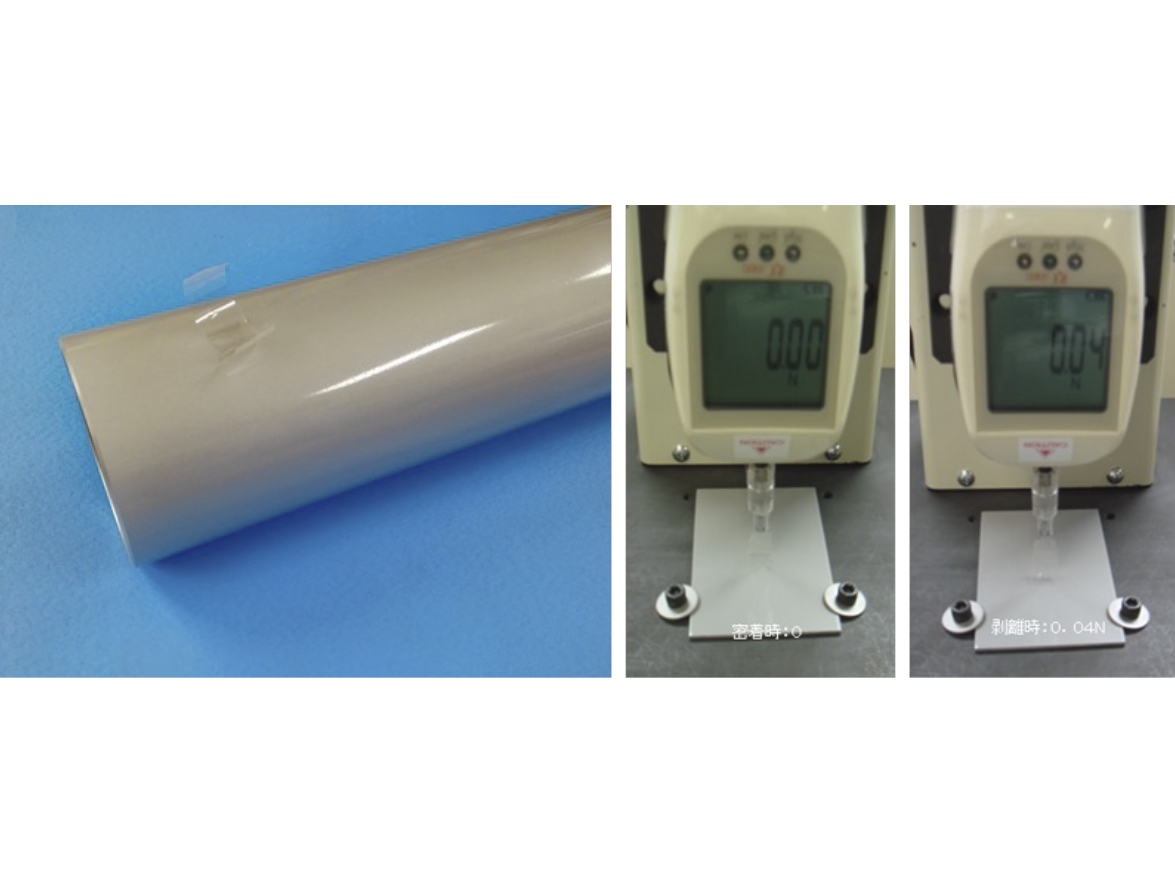

NP-1 Roller

By reducing the surface energy of the roller, wrinkles and damage to the base material that often occur on the hip and conveyor rolls are minimized, and peel ability is improved.

The roller reduces roughness on the opposing side, preventing contamination. Unlike conventional rubber surfaces, which deteriorate over time, NP-1’s surface chlorine modification treatment significantly enhances durability, preventing deterioration. This surface treatment is also environmentally friendly.

To examine the effect of component elution from EPDM rubber, the film’s surface energy was measured before and after contact with the opposing film.

Rolls to Prevent Damage During Transport

Traditionally, satin plating is applied to the surface of guide rolls to improve the releasability of the film. However, as the film base material becomes thinner, the film surface becomes more susceptible to damage. Thanks to our experience with polishing technology, we can reduce the damage that satin-plated rolls cause to the film during transport.

Purpose of a Matte Finish on the Roll Surface

If the roll surface is smooth or mirror-finished, a vacuum will be created between the film and the roll during transport, causing wrinkles to appear on the film. To prevent wrinkles, the roll surface can be made matte, allowing air to escape between the special protrusions.

The guide rolls installed on film production lines are HCr plated (mirror/matte finish) and are used for a variety of purposes. Particularly during the transportation process, the roll surface is treated with a matte finish and then chrome plated to improve film peeling and prevent any blocking. This roll polishing technology aims to prevent film surface scratches that occur after satin finishing.

Purpose: Conveyor guide roll for thin film, metal foil, and processed-based film.

Nip Roll

The Nip Roll offers wrinkle prevention and stable feeding due to low tension. Surface treatments can be applied according to the application. The “MX roll for wrinkle removal/meandering prevention” is a measure to prevent wrinkles, considering lower tension, better grip, and reduced stress when running the material. This roll allows for stable running of the base material and stabilization of quality.

In addition to the lineup of “narrow angle conveyance” and “wide angle conveyance,” you can choose the special surface treatment that suits your application.

Features:

- Max length: 5000mm

- Surface processed with a special double helical groove

- Prevents wrinkles, reduces tension, improves grip, and reduces material stress

- Measures the stability of the base material and quality

- Special processing of the rubber roll surface according to the application

Dust Removal Roll

Equipped with special synthetic rubber, this roll offers excellent adhesion, stability, heat resistance, and durability. The flexible material and soft adhesion provide a uniform and effective dust removal. You can choose from strong to weak dust removal power depending on the purpose of use. The product is easy to clean and can be used for a long time.

Features:

- Excellent weather and ozone resistance

- Low charge on the roller, minimizing static electricity generation due to friction or peeling

- Distortion suppression treatment on the rubber roll surface

- Prevents base material contamination by minimizing extractables from internal rubber components

Purpose:

- Removing dust from printed circuit boards

- Removing dust from optical films such as polarizer films

- Removing dust from photoengraving materials

- Dust removal from gravure printing lines for plastic films and sheets

- Dust removal from previous processes such as screen printing and card printing

- Cleaning of metal plate processing

PVA Water Absorption Sponge Roll

This roll has strong hydrophilic properties and excellent water absorption ability, making it ideal for draining rolls. It boasts high abrasion resistance and excellent durability when retaining water. With continuous pores, it offers low resistance, excellent filtration performance, and can adapt to changes in pore size and shape.

PVA-HG Water Absorption Sponge Roll

Compared to conventional PVA sponges, this roll has significantly improved elasticity, water absorption, and abrasion resistance. It also features measures to prevent staining when water is absorbed, with enhanced performance. Additionally, we offer the HG-G lineup, which aims to further improve wear resistance.

Purpose:

- Draining water after washing printed circuit boards, etc.

- Drainer related to display glass

- Nip roll

- Sponge roll for humidification and compression

- Wiping material

Lightweight Carbon Roll

Using CFRP (Carbon Fiber Reinforced Plastics) for the shaft, even long rolls can be coated without being affected by their own weight.

The excellent performance of CFRP enables high speed, lighter weight, wider width, higher precision, loss reduction, compact design, reduced deflection, load reduction, and improvement of the work environment. This will address various issues associated with metal rolls.

It is now possible to produce long rolls (Max: up to 5,550L).

Using a CFRP pipe, the journal part is made of metal such as aluminum, SUS, SS, etc., and is bonded to the shaft part with a high-performance adhesive. Generally, when CFRP rolls are used alone, there is a possibility that problems such as hairline cracks may occur on the CFRP surface during operation. Therefore, the roll surface is covered with a thin metal sleeve (Al/SUS) like a normal metal roll. We offer rubber lining, fluorine coating, nano ceramic coating, ceramic thermal spraying, etc.

Features:

- Faster speed

- Lighter weight

- Wider width

- High precision

- Loss reduction

- Compact design

- Deflection reduction

- Load reduction

- Improved working environment

Purpose:

- Lightweight due to composite construction

- Guide roll compatible with longer lengths

- Various conveyor rolls

NP-1 Roller

By reducing the surface energy of the roller, wrinkles and damage to the base material that often occur on the hip and conveyor rolls are minimized, and peel ability is improved.

The roller reduces roughness on the opposing side, preventing contamination. Unlike conventional rubber surfaces, which deteriorate over time, NP-1’s surface chlorine modification treatment significantly enhances durability, preventing deterioration. This surface treatment is also environmentally friendly.

To examine the effect of component elution from EPDM rubber, the film’s surface energy was measured before and after contact with the opposing film.

DLC Coating Roll

Coating the roll surface with DLC (Diamond-Like Carbon) offers several benefits:

- Low friction coefficient:0.2 or less

- High hardness and wear resistance:DLC (Max 2200HV)

- Scratch prevention:Harder film than HCr

- Alternative to fluoro-resin coated rolls:Higher hardness than fluoro-resin coating

- Corrosion resistance:Improved chemical resistance

- Hydrophilicity:Water contact angle of 20-30 degrees, improving wettability

- Electrical resistance value:10^6 to 10^10 ohms (antistatic, preventing dust adhesion)

Maximum Processing Size:

- 300 diameter core x 2500L x 2800TL (Max: 300kg)

- Maximum film thickness: 6µm

- Since the film is formed at room temperature, it is also possible to coat materials that are sensitive to heat.

Coating Examples:

- Various conveyor rolls (prevents damage to conveyed items and reduces friction)

- Film coating equipment (thin film coating)

- Stretching roll/rolling roll (prevents scratches on film and reduces friction)

- Roll for slitter

- Surface treatment of drive parts (reduces friction and improves wear resistance)